Project Description

Drip Coffee Bag Filling Packing Machine

Sprficication

| Model | XY-188-4Z |

| Bag size | Inner bag: L 50-74mmX W 50-90mm Outer bag: L 85-120mmX W 75-100mm |

| Bag material | Inner bag: Non-woven fabric, nylon filter cloth, corn fiber Outer bag: Composite film, pure aluminum film, paper film, etc |

| Bag sealing method | Inner bag: ultrasonic sealing 3-side Outer bag: heat sealing 3-side |

| Speed | 20-35 bag/min |

| Filling range | 1-20g |

| Contact material part | ss304 |

| Filling accuracy | ≥99% |

| Air consumption | ≥0.6m³/min |

| Power | 3.7KW |

| Voltage | 220V/1 Phase/50HZ Or customized |

| Dimension (LxWxH) | Approx. 1250*760*2350mm |

| Weight | Approx. 660kg |

* Above is the standard model technical parameters, other special requirements and functions, can be customized!

Product Description

The automatic drip coffee filling machine is mainly designed for filling disposable packaging of small or medium size bags. It can be widely used in coffee powder drip bag, tea bag, herbal tea bag, health tea roots bag, etc. The inner bag is made of degradable food packaging filter material with ready-made hanging ear, outer bag can help to ensure the fresh taste of the coffee powder or tea.

Ultrasonic sealing suitable for inner non-woven packaging material cutting, 100% sealing rate and tight sealing. Thermal sealing for outer plastic sealing.

This drip coffee bag packing machine is mainly used to pack coffee powder, coffee beans and small granular products.

High position accuracy, stable driving, precise dosage, and simple operation.

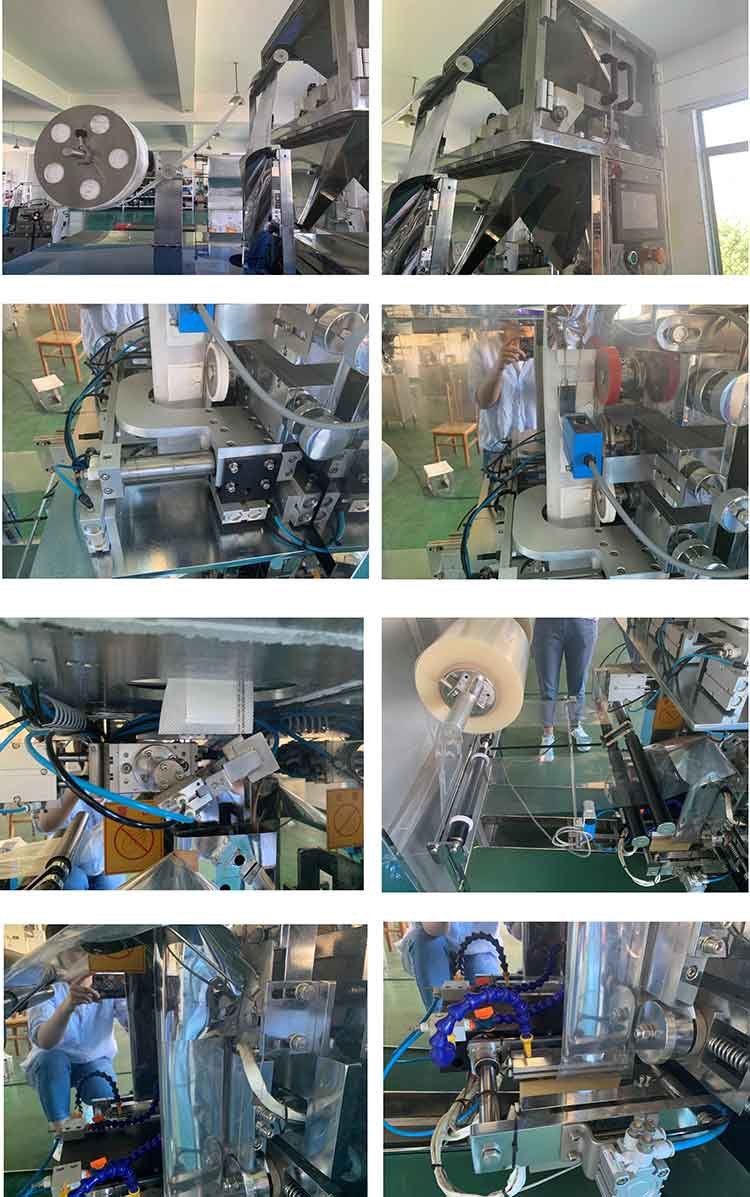

Working Process

- Inner drip bag roll

- Inner drip bag form (side sealing and bottom sealing)

- Coffee powder filling

- Inner drip bag sealing and cutting

- Outer bag roll

- Outer bag form (side sealing and bottom sealing)

- Inner drip bag filled in the outer bag by mechanical arm

- Outer bag sealing and cutting

- Finished products exit

Features

- Ultrasonic inner bag sealing is suitable for all the non-woven packaging material sealing and cutting, finish product rate is closed to 100%. great sealing effect, beautiful pocket

- The inner bag roll is non-woven filter bag with ready-made hanging ear, the finished drip coffee bag can be hanged on the edge of the cup, Better coffee brewing taste and beautiful bag shape make it very popular at abroad market.

- Outer bag is Composite film, which can be heat sealed, intelligent control temperature controller, temperature control more accurate. Outer bag adopts photoelectric sensor orientation so that bag length more accurate and artistic.

- Volumetric measurement filling, the drip coffee bag filling machine can finish inner and outer bag form, filling, sealing, cutting, counting, date print and finished product exit.

- PLC control system, Simple structure, easy in installation and maintenance.

- Main electrical elements adopt famous well-known brand.

- Machine body is made by high quality stainless steel 304, easy to clean.

- Optional device are nitrogen filling device, date print and mixing device.

COMPANY AND WORKSHOP