Project Description

Aluminum Tube Filling Folding Machine

Specification

| Model | AF-40 |

| Tube material | Aluminum metal tube |

| Packing Speed | 30-50 pcs/min |

| Filling Volume | 5-30ml/25-250 ml |

| Hopper volume | 35L |

| Tube Diameter | Φ10- Φ50 |

| Tube Height | 50-220mm |

| Power | 1.1KW |

| Filling error rate | +-1% |

| Voltage | 220V/1Phases/50/60HZ Or customized |

| Air Pressure | 0.4Mpa |

| Dimension (LxWxH) | 2250*850*1650mm |

| Weight | 500kg |

* Above is the standard model technical parameters, other special requirements and functions, can be customized!

Product Description

The aluminum tube filling folding machine is suit for the filling and sealing of metallic aluminum tube. The machine is specially designed for clients to manufacturer instant glue, chemical or medicine. A dual four-fold sealing is reached after each turn of a station. Because it is safe and airtight, so we can ensure the excellent quality of the products. This machine adopts unlimited adjustment speed and photoelectric control. No tube no filling. As for different metal tube, we can do it just through put on the mold with different diameters.

This filling and sealing machine are widely used in pharmaceutical, cosmetic, food and chemical industries etc., it is applicable in various aluminum tube, which fill pack all kind of Such as ointment, adhesives, AB glue, Neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste and else liquid, lotions and cream etc.

Working Process

- Tube loading one by one auto (AF-40) or by hand (BAF-40)

- Color mark orientation and tube detecting

- Auto Filling, no tube no filling, 2 hoppers for 2 glues

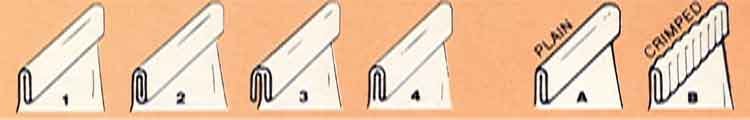

- Folding (3 folds or 4 folds): flattening → crimping 90° → flattening → crimping 90° → flattening → crimping -90° → flattening with date code

- Discharging

- Can be connected with hydraulic press machine for high viscous product fill.

Features

- Tube feeding to rotary table automatic.

- No tube not filling, overloading protection.

- Manual Insert the metal tube into the index plate tube holder, using the machine drive automatism locomotion, photo electricity inspect that confirm tube Basel have tube and then automatism filling the tube, after four-fold sealing.

- The filling quality easy to adjust, the filling quality is tunable, the computation precision is higher. This machine adopts the high-quality stainless steel material to make of contacting the material

- If your materials need to heat, the external heating thermostat device can be installed outside the hopper.

COMPANY AND WORKSHOP