Project Description

Heat Shrink Wrapping Machine

Product Description

- The sleeve-type heat shrink wrapping machine is made of high-quality steel or stainless steel. The structure is compact and reasonable, durable and energy-saving. The new plastic wrap machine is widely used in combination packaging of beverages, food, pharmaceutical, book, and chemical products. No need for bottom support, no matter square, round or flat, it can be packaged perfectly, the visual effect is very good, and the packaging cost is low.

- This shrink film packaging machine adopts PLC automatic control, man-machine interface tracking and accurate positioning. Bottles, flexible adjustment, safe and beautiful. Adjustable hot air circulation structure, applicable to various existing heat shrinkable films (including color printing), film replacement is quick and easy, fault warning, complete locking and reliable operation. Therefore, it provides a solid guarantee for constant quality, stable and reliable, and long-term continuous production.

Process

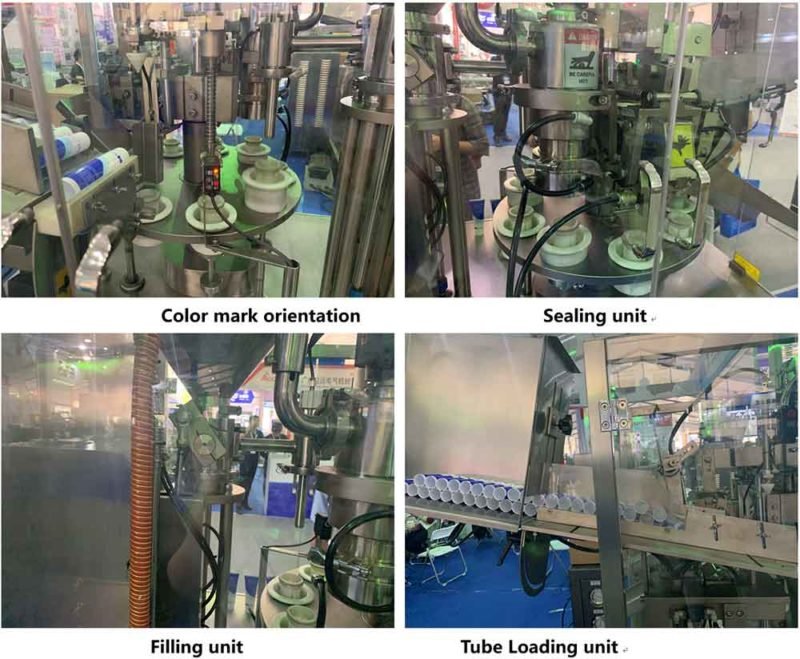

- Auto box loading

- Film loading auto

- Film cutting and sealing

- Heat shrink

- Cooling

Features

- The bottle or box to be packaged reaches the bottle stopper plate along the passage formed by the bottle dispensing mechanism along the bottle dividing mechanism.

- The signal is given by the upper photoelectric detecting head, the bottle (box) machine is stopped, the baffle is retracted, the stress of the conveying extrusion is released, and the partition is raised to separate the packaging bottle (box) from the waiting bottle (box).

- The pushing mechanism works forward to bring the bottle (box) along the guide bottle (box) mechanism together with the film to the sealing and cutting position, and pushes the bottle of the previous completed film into the conveyor belt in the heat shrinking device.

- The film feeding mechanism also works at the same time. Then the heat sealing cutter moves downward to complete the sealing and cutting function.

- The bottle pushed onto the high-temperature conveyor belt performs the heat-shrinking function while moving forward in the heat-shrinking device, and finally reaches the finished product carrying device after being cooled and contracted by the cold air.

- The above process is repeated continuously to achieve packaging automation in this shrink wrapping machine.

| Model | LC-500A |

| Cutting type | Sleeve type sealing |

| Running speed | 25 packs/min |

| Max packaging size | L: 320mm, W: 150mm, H: 200mm |

| Film | PE heat shrink film |

| Max film size | Width: 400mm, outer diameter: 280mm |

| Tunnel oven size | L: 1200mm, Entrance 450x220mm(WXH) |

| Tunnel conveyor | Teflon mesh belt converyor |

| Conveyor speed | 40m/min can be adjusted |

| Height of the plate | 850-900mm |

| Air pressure | <=0.5MPa |

| Main Power | 9.5KW |

| Voltage | 380V, 50-60Hz 3 phase |

| Weight | Approx. 600KG |

Your Content Goes Here