Project Description

Ultrasonic Soft Tube Filling Machine

Specification

| Model | FS-009 |

| Tube material | Plastic/laminated tube |

| Packing Speed | 15-28 pcs/min |

| Filling Volume | 10-120ml/25-250 ml |

| Hopper volume | 30L |

| Tube Diameter | Φ10- Φ50 |

| Tube Height | 50-220mm |

| Power | 2KW |

| Filling error rate | +-1% |

| Voltage | 220V/1Phases/50/60HZ Or customized |

| Air Pressure | 0.55-0.65Mpa |

| Dimension (LxWxH) | 1300*900*1650mm |

| Weight | 550kg |

Introduction

This filling and sealing machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc., it is applicable in various aluminum plastic compound soft tube, plastic soft tube which fill pack all kind of Such as ointment, adhesives, AB glue, Neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste and else liquid, lotions and cream etc.

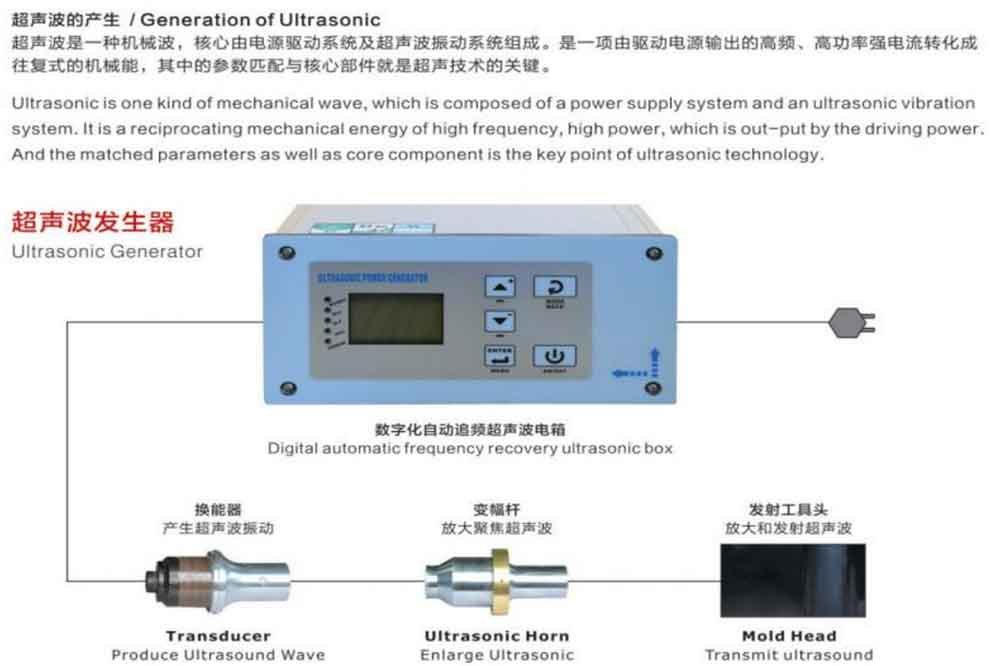

Compared with heat sealing, the ultrasonic tube sealing has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, different shape sealing

* Lower power consumption, energy saving

Application

Tube Type: plastic soft tube, aluminum plastic laminate tube

Filling Material: all kind of ointment, adhesives, epoxy glue, skin cream, hair cream, boots oil, toothpaste, liquid, lotion, sauce, cream, etc.

Working Process

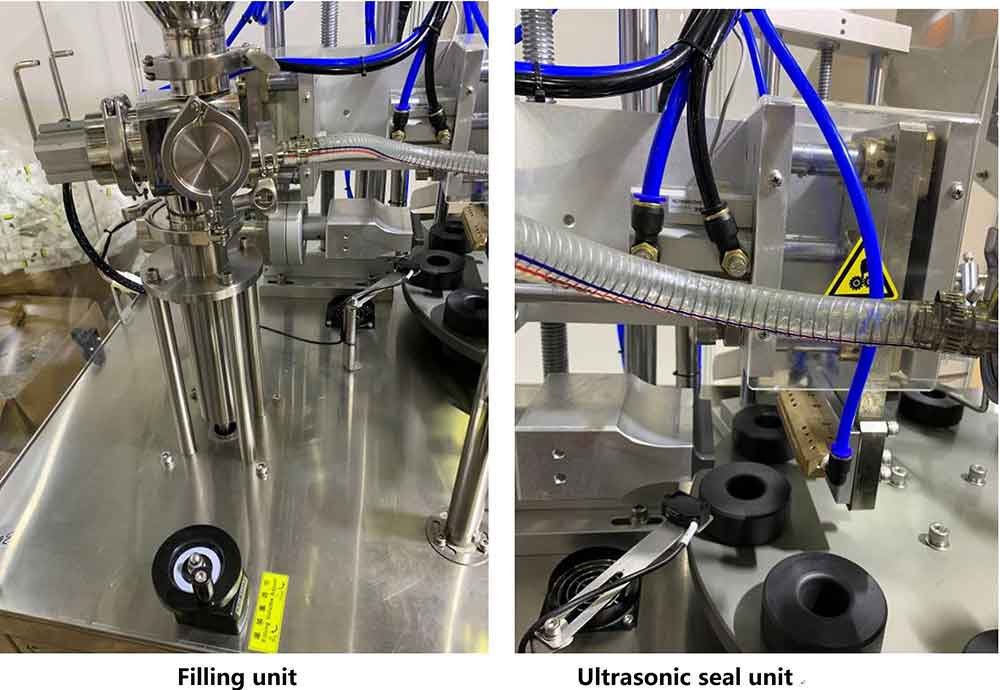

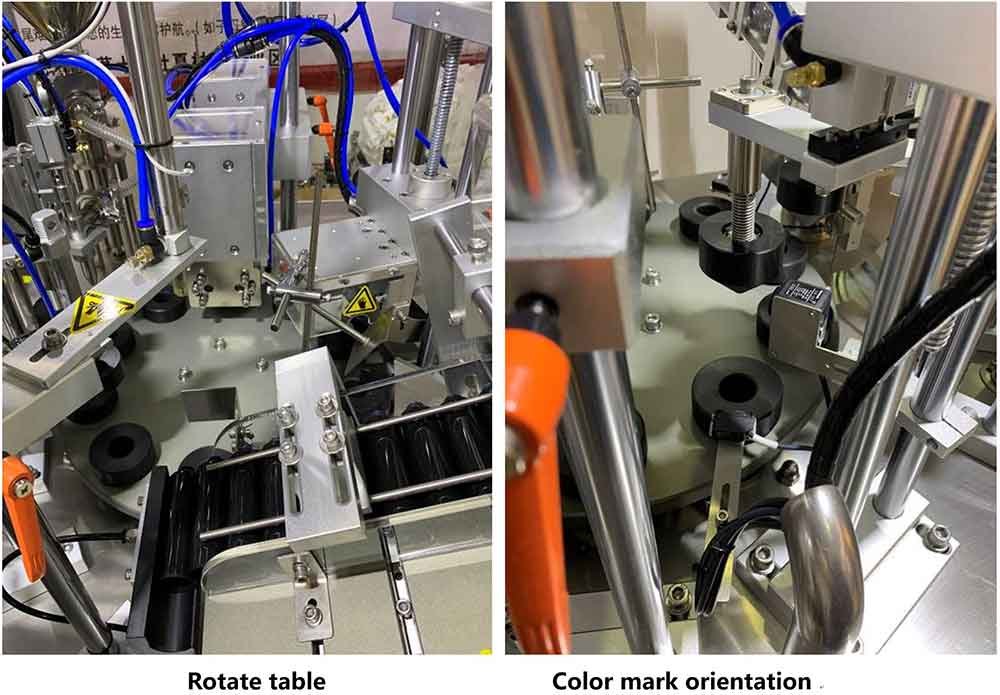

- Automatic tube loading one by one

- Color mark orientation and tube detecting

- Auto Filling

- Ultrasonic sealing and date coding

- Cutting

- Discharging

- Transporting (Optional device, If connected with conveyor belts)

Features

- Tube feeding to rotary table automatic.

- No tube no filling, overloading protection.

- Adopted with air cut leak-proof nozzles, the filling volume can be adjusted easily.

- Ultrasonic sealing and date coding on one station can seal one or two layers plastic tube, with different shape tails. Sealing performance is stable, clear lines, and beautiful tail.

- Digital ultrasonic automatic frequency chasing electric box, developed ourselves, has the function of increasing the power automatic compensation, do not need to adjust the frequency manually. It will not cause the machine power to reduce due to long-time use, can adjust the power according to the tube material and size, the failure rate is extremely Low, longer life.

- High filling accuracy, Adjustable, and stability heating time, beautiful, tidy, solid, and health sealing appearance, Flat Trimming.

- If your materials need to heat, the external heating thermostat device can be installed outside the hopper.

COMPANY AND WORKSHOP